PROJECT IN PROGRESS

CAPACITÀ PRODUTTIVA STAMPA

CAPACITÀ PRODUTTIVA ACCOPPIATO

PROJECT ENDED IN 2022

SafeHCP for you.

Siamo attenti al tuo quotidiano: entriamo nel tuo “momento” proteggendolo e senza mai sconvolgerlo.

Intelligente, preserva la tua salute e le tue abitudini.

Protezione mai banale, sempre oltre gli standard.

Adattabilità, materiali flessibili che si adattano alle tue esigenze.

Resistenza, capace di resistere nel tempo.

Check-up preliminare degli attuali materiali di imballaggio in uso.

Soluzioni alternative più economiche, scalabili e sostenibili.

Informazione, trasparente verso lo user finale.

Immagine, consapevolezza e utilità per una protezione di valore.

Allflex Design Hub.

Ascolta. Crea. Applica

We are MAKER

Progettare un design capace di proteggere e comunicare un prodotto. Ecco cosa sappiamo fare…

Il packaging è solo il risultato di un costante lavoro di progettazione, attenzione e creazione: progettare un design capace di proteggere e comunicare un prodotto, razionalizzando dei costi, ottimizzando gli scarti di materie prime e sposando (appieno) il concetto di utilità come unica risposta alle necessità del cliente (sempre più esigente e sempre più attore principale di un mercato in continua evoluzione);

una sapiente (quanto intelligente) combinazione di film e carte laccate che permettono ai nostri clienti di risparmiare sull’acquisto e, nel contempo, di ridurre gli scarti grazie ad una mirata stratificazione dei materiali da noi offerti.

In questi casi diventa fondamentale l’ascolto attivo del nostro cliente: comprendere le sue reali necessità significa avere la fiducia e la libertà di “osare” per lo sviluppo di nuove soluzioni di packaging. Dal progetto al prodotto finito: pensiamo e facciamo HCP.

Qualità certificata.

Oltre gli STANDARD

…per superare noi stessi. Una qualità apprezzata e certificata.

– nella qualità delle materie prime impiegate sono di alta qualità;

– nel controllo costante del processo produttivo;

– nei testing di produzione (in linea con i livelli di accettazione richiesti).

Investiamo molte delle nostre risorse in strumenti all’avanguardia per il controllo delle materie prime: ogni lotto ricevuto non può essere immesso all’interno del ciclo produttivo se prima non ha superato tutta una serie di rigorosi controlli qualità interni (grazie anche ad un sofisticato e moderno sistema di ERP).

CERTIFICATO ISO 9001 : 2015 [Leggi]

Politica e cultura di qualità [Leggi]

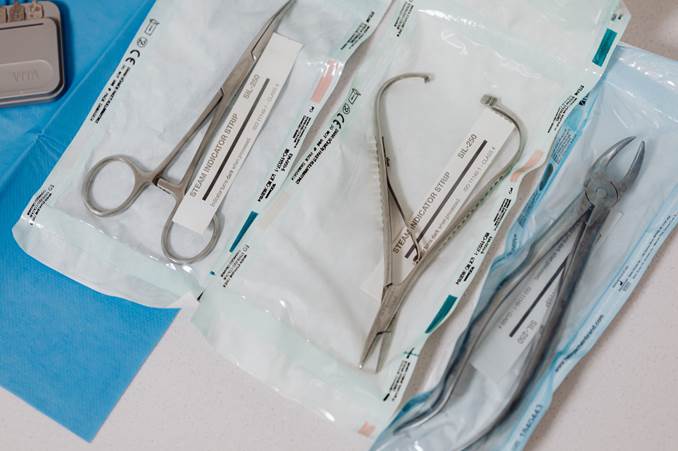

Packaging medicale e farmaceutico.

SAFE HCP: la nostra vocazione oltre gli standard.

Che si tratti di stampa di film, carta, Tyvek o produzione di laminati per pellicole e pellicole per applicazioni flowrap, termoformabili, barriera o buste, guardiamo al nostro imballaggio con questa consapevolezza: creando un involucro e proteggendone il contenuto, stiamo facendo qualcosa di “straordinario”.

Presidio territoriale.

Ad oggi, contiamo due sedi commerciali (UK e USA) e due stabilimenti produttivi: uno a Carpi (in Italia, ad appena un’ora a nord di Bologna) e l’altro nella vicina Repubblica di San Marino.

Queste due strutture sono equipaggiate identicamente, si supportano reciprocamente garantendo il massimo rispetto degli standard qualitativi (e di sicurezza) dei nostri prodotti.

Insieme. Presenti.

All Flex S.p.a.

(Repubblica di San Marino)

Via Fabrizio da Montebello, 67

47893 Acquaviva

RSM

All Flex S.r.l.

(Italia)

Via Degli Scariolanti, 10

41012 Carpi (MO)

ITA

All Flex UK Ltd.

(United Kingdom)

6 Burden Park, Clevedon,

North Somerset, BS21 7GB

UK