PROJECT IN PROGRESS

PRODUCT CAPACITY PRINT

PRODUCT CAPACITY LAMINATE

PROJECT ENDED IN 2022

SafeHCP for you.

We are attentive to your everyday: we enter your “moment” by protecting it and never disrupting it.

Smart, it protects your health and habits.

Protection never trivial, always beyond the standards.

Adaptability, flexible materials that adapt to your needs.

Resistance, it can last over time.

Preliminary check-up degli attuali materiali di imballaggio in uso.

Alternative Solutionscheaper, scalable and sustainable.

Information, transparency towards the end user.

Image, awareness and usefulness for a protection of “value”.

Allflex Design Hub.

Listen. Create. Apply.

We are MAKER

Creating a design that can protect and communicate a product. That’s what we know how to do…

Packaging is only the result of constant planning, attention and creation: creating a design that can protect and communicate a product, rationalizing costs, optimizing raw material waste and (fully) embracing the concept of usefulness as the only answer to the needs of the customer (who is increasingly demanding and becoming the main player in a constantly evolving market);

a wise (as well as smart) combination of films and lacquered papers that allow our customers to save on purchases and, at the same time, reduce waste thanks to a focused stratification of the materials we offer.

In these cases, active listening to our customer becomes essential: understanding their real needs means having the confidence and freedom necessary to “dare” to develop new packaging solutions. From the project to the finished product: we think and make HCP.

Certified quality.

Beyond the STANDARD

…to outdo ourselves. An appreciated and certified quality.

We firmly believe:

– in the quality of the raw materials used, which are of high quality;

– in the constant control of the production process;

– in production testing (in line with the required acceptance levels).

We invest many of our resources in cutting-edge tools for the raw material control: each batch received cannot enter the production cycle if it has not first passed a series of strict internal quality controls (thanks also to a sophisticated and modern ERP system).

CERTIFICATE ISO 9001 : 2015 [Read more]

Policy of quality [Read more]

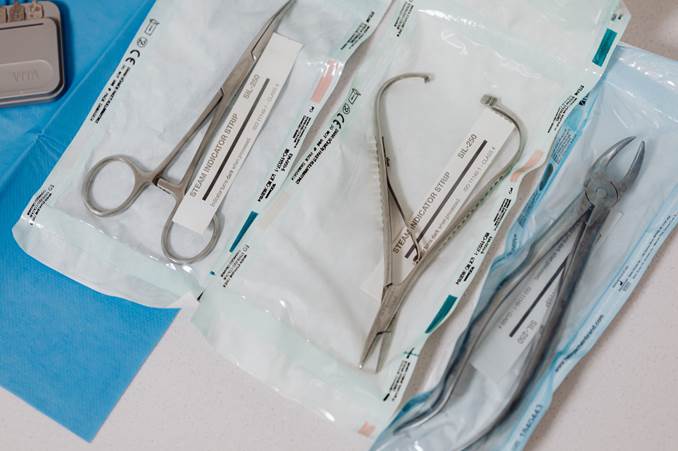

Healthcare, medical and pharmaceutical packaging.

SAFE HCP: our vocation beyond standards.

Whether printing film, paper, Tyvek®️ or film laminates and foils for flowrap, thermoforming, barrier films or pouches, we look at our packaging with this understanding: creating a packaging protecting the devices, we are doing something “extraordinary”.

Territorial presidium.

To date, we have two sales offices (UK and USA) and two production plants: one in Carpi (in Italy, just an hour north of Bologna) and the other in the nearby Republic of San Marino.

These two facilities are equipped identically, mutually supporting each other ensuring maximum compliance with the quality (and safety) standards of our products.

Together. Present.

All Flex S.p.a.

(Repubblica di San Marino)

Via Fabrizio da Montebello, 67

47893 Acquaviva

RSM

All Flex S.r.l.

(Italia)

Via Degli Scariolanti, 10

41012 Carpi (MO)

ITA

All Flex UK Ltd.

(United Kingdom)

6 Burden Park, Clevedon,

North Somerset, BS21 7GB

UK